Training Course Topics

PLC Hardware Basics Training Course

- Intro

- Prerequisites

- Objectives

- What is a

PLC?

- PLCs Form Factor

- Stand Alone

- Modular

- Form Factors

Cost and Capabilities

- PLC

Chassis

- Physical

Features

- Backplane

PCB

- Module

Installation

- Chassis

Selection guide

- Allen Bradley

SLC 500 Chassis

- PLC Power

Supply

- What is a PLC

Power Supply?

- Physical

Features

- Output Power

- Sizing Allen

Bradley 1746-P1 Power Supply

- PLC

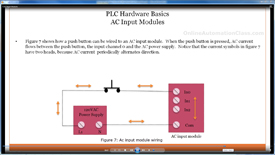

Digital Input and Output Channels

- What are Input

and Output Channels?

- Digital I/O

Module

- Operating

Voltage Range

- Allen Bradley

SLC 500 I/O Modules

- Digital I/O

Module

- Physical

Features

- Digital Input

Channels Wiring

- Sinking and

Sourcing Input Wiring

- Input Channels

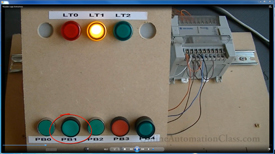

Wiring Demo

- What are

transistors Output Channels?

- Transistor

Output Channels Current Rating

- Number of

Channels

- Transistor

Sinking and Sourcing Output Channels Wiring

- Output Channels

Operating Voltage Range

- Transistor

Output Channel Wiring Demonstration

- PLC Contact Output

Channels

- What Are Contact

Output Channels?

- Contact Types:

Form A, Form B, Form C.

- Contact Output

Module Internal Connection

- Voltage and

Current Rating

- Sourcing and

Sinking

- Contact Output

Channels Wiring Demonstration.

- PLC Analog Input

Channels

- What are Analog

Input Channels?

- Examples of

Practical Usage

- Types of Analog

Signals

- Examples of

Analog Input Channels Usage

- Operating

Voltage Range

- Allen Bradley

Analog Input Module

- Measurement

Accuracy

- Module

Resolution

- Voltage

Resolution Calculation

- Total Counts

Calculation

- Analog Input

Module Usage Demonstration.

- PLC Analog Output

Channels

- What are Analog

Output Channels?

- Examples of

Practical Use

- Physical

Features

- Operating

Voltage Range

- Module

Resolution

- Accuracy

- Usage

Demonstration

- Voltage

Resolution Calculation

- Counts

Calculation

- Analog I/O

Channels Wiring

- Electrical Noise

Prevention

- Cable

Shielding

- PLC

Processor

- What is a PLC

Processor?

- Examples of PLC

Processors

- Physical

Features of PLC Processors

- Indicator LEDs

and Keylock

- Communication

Ports

- Programming

Cable

- Memory Type:

ROM, RAM, EEPROM

- Memory

Structure

- Memory Capacity

Selection

- User Programs

and Firmware

- Scan

Cycle

- Scan Cycle

Analogy.

- Scan

Time

- Powering

PLCs

- Power

Requirement

- What is a

Control Transformer?

- Control

Transformer Terminal Name

- Step Down

Control Transformer

- Control

Transformer Sizing

- Volt-Amp

Rating

- PLC Rating

Label

- PLC

Power

- Control

Transformer Fuse Sizing

- Programming

PLCs

- PLC Interface

Software: RSLOGIX 500 and DirectSOFT

- PLC Program

Upload and Download

- Interface

Software Function

- RSLOGIX 500 Pro

Quick Tour

- PLC

Communication interfaces: RS232, RS485 and Ethernet

- Handheld

PLC Programmers

PLC

Programming Basics

- Training course

introduction

- PLC Memory

- Introduction

- PLC Memory Usage

- Data

Types

- Integer,

Boolean, Floating Point, counter and timer

- Data Type

Usage

- Boolean Data

Type

- Boolean Data

Type Block

- Integer Data Type

- Integer Data

Type Block

- Memory

Addressing

- Allen Bradley

Memory Addressing Convention

- RSLOGIX 500

Binary Data File

- PLC Program Overview

- Introduction

- Why some

machines require PLC programs?

- PLC Program

Inputs and Outputs

- PLC Programs

Instructions

- PLC Program

Development Software

- Ladder Logic

Programming Language

- Ladder logic

Instructions

- Reference Memory

Address

- Ladder Logic

Instruction Symbol Name

- Ladder Logic

Comments

- Ladder Logic

Rungs

- Ladder logic

Rungs State

- Ladder Logic

Branches

- PLC Program

Scan

- PLC Program

Execution

- Ladder Logic

Program VS Electrical Ladder Logic Diagram

- "RSS" RSLOGIX 500

Project Files

- RSLOGIX Micro

Starter Lite Installation

- Open RSS project

file with RSLOGIX Micro Starter Lite

- Ladder Logic

Instructions

- Ladder Relay

Instructions Introduction

- Normally open

contact instruction

- Normally closed

contact instruction

- Output coil

instruction

- Normally open,

normal closed and output coil instruction demonstration

- Transitional

contact instruction Demonstration

- Latch output

coil instruction

- Unlatch output

coil instruction

- Latch and

unlatch output coil instruction demonstration.

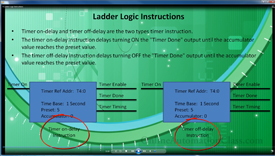

- Timer

instruction

- Instruction

inputs and outputs.

- parameters

- Reset

- Analogy

- Demonstration

- Counter

instruction

- Instructions

input and outputs.

- Instructions

parameters.

- Reset

instruction.

- Analogy.Demonstration.

- Ladder Logic

Programming Tools

- Introduction

- Boolean

Expression

- Boolean

Expression to Ladder Logic Circuit Conversion

- Sum of Product

(SOP) & Product of Sum (POS) Boolean Expression

- SOP boolean

Expression Conversion Example

- POS Boolean

Expression Conversion Example

- Truth Table

Introduction

- Truth Table

Header

- Truth Table

Input Columns

- Truth Table to

Boolean Expression Conversion Example

- Karnaugh Map

Introduction

- Karnaugh Map

Vertical and Horizontal Header

- Karnaugh Map

Output Cells

- Karnaugh Map

GraCy ode

- Number of Inputs

vs Number of Output Cells

- Inputs to Output

Cell Mapping

- Karnaugh Map

Usage Example

- Karnaugh Map

Grouping Rules

- Solving Karnaugh

Maps with "Karnaugh Map Minimizer" Software

- Types of PLC

Programs

- Introduction

- Combinational

PLC Program

- Combinational

PLC Program Characteristics

- How

Combinational PLC Programs Work

- Sequential PLC

Programs

- Sequential PLC

program Characteristics

- How Sequential

PLC Programs Work

- Sequential PLC

Program Analogy

- Sequential PLC

Program Application

- Combinational

PLC Program Application

- Combinational PLC

Program Design

- Introduction

- PLC Program

Development Cycle

- Machine Logic

Specification Step

- Electrical

Schematic Drafting Step

- Design &

Implementation Step

- Expressing

Systems Logic with Truth Table

- Truth Table to

Boolean Expression Conversion

- Boolean

Expression to Ladder Logic Circuit Conversion

- Combinational

PLC Program Overview

- Testing

step

- Combination PLC

program demonstration

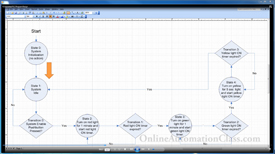

- Sequential PLC

Program Design

- Introduction

- Sequential PLC

Program Development Cycle

- Machine/System

Logic Specification Step

- Systems Logic

Documentation

- System I/O

Documentation

- Hardware

Schematic Drafting Step

- Design &

Implementation Step

- Sequential PLC

Program Logic Overview

- State Diagram

Design

- State Diagram to

Ladder Logic Conversion

- Testing

Step

- Sequential PLC

Program Demonstration

Sales Policy

- 30 days money back if not satisfied.

|